Project Details

Industries:

Services:

Scope & Objectives

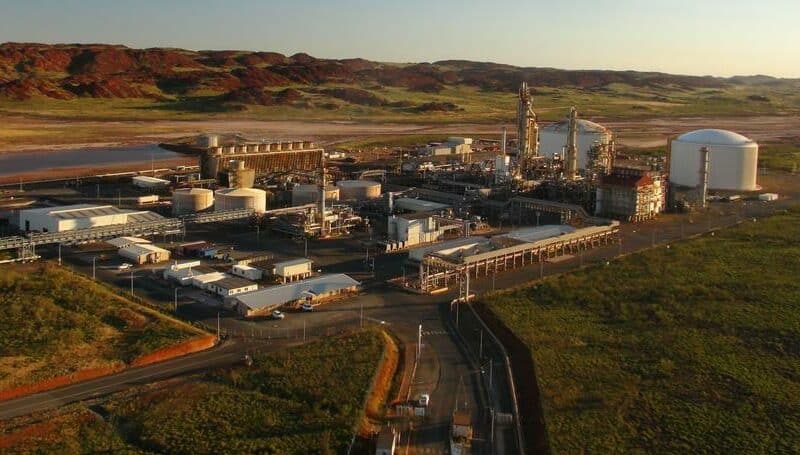

Pluto Gas Plant Waste Heat Recovery Unit – GTG Exhaust Stack Repair

A pivotal element in the GTG exhaust stack system was the control door, which was responsible for redirecting excessive waste heat. Our client pinpointed two functional deficiencies with the door – an impaired sealing capability and door hinge misalignment causing clashes with surrounding equipment. Contending with the less than ideal conditions, Handleys was marshalled to scrutinise and propose solutions for these issues during a confined shutdown window.

The Challenge

The complexity arose with the exhaust stack being off limits during normal operations due to hazardous heat levels and toxic waste fumes. The door’s sequestering location, inhospitable workspace, temporal constraints, and the presence of concurrent work fronts were additional hurdles. With seals and hinges placed diametrically on the exhaust stack and the hydraulics responsible for door operation located externally, we had our work cut out for us.

Our Solution

Our team relished this complex challenge. We deployed laser scanning technology to acquire comprehensive 3D data of both door sides, the external hinge, and the hydraulics. To ensure meticulous rectification, we extended our scans to include all internal seals and exhaust walls, thereby crafting a complete 3D replica of the complex area.

By utilising advanced 3D CAD software, we were able to draft a simulation of the door’s swinging action. This model aided us to:

- Foresee its position when fully ajar

- Survey potential seal misalignments

- Discover possible clash points with the walls

- Calculate the necessary hinge adjustments

Armed with these insights, and the control door temporarily removed, we guided fabricators in making precision adjustments to the hinges.

The Results

With reinstallation done right, operation of the reconfigured door confirmed our success. The key achievements on this job include:

- Effective sealing – issue solved

- Elimination of all equipment clashes

- Client satisfaction with minimum downtime

- Expedited with 100 per cent safety