Project Details

Industries:

Services:

Scope & Objectives

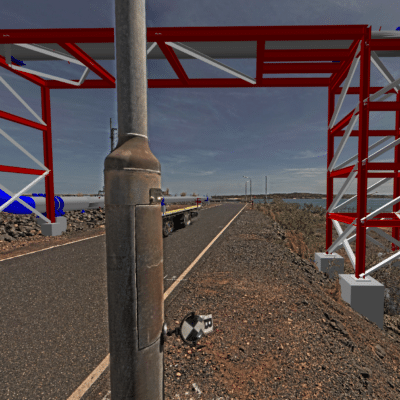

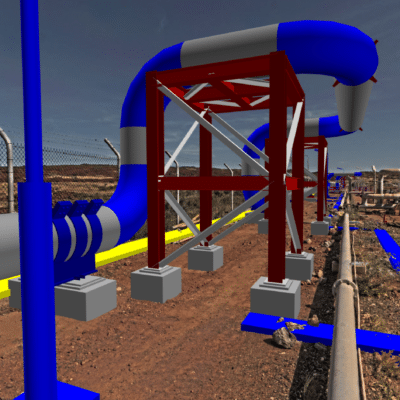

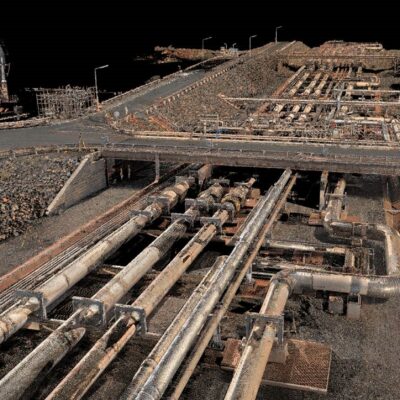

Pluto-KGP Interconnector Pipeline – NEO Foundation Survey

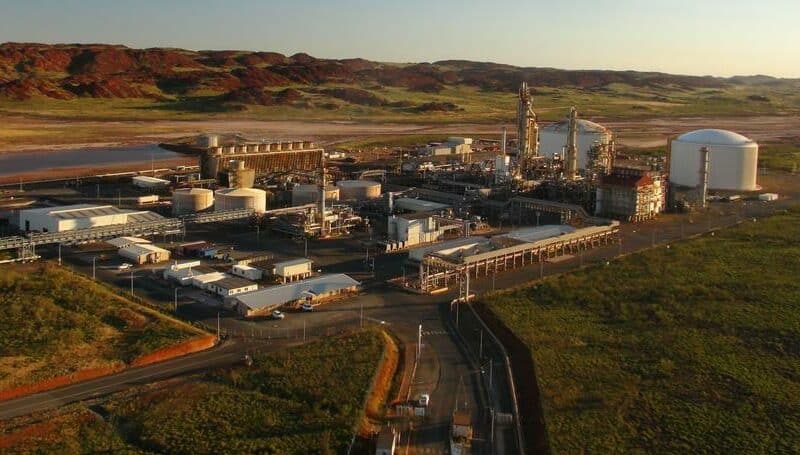

The Interconnector links offshore Pluto fields to the North West Shelf Project’s Karratha Gas Plant (KGP). The gas is piped 5km to KGP via a pipeline nestled within the existing Dampier to Bunbury Natural Gas Pipeline (DBNGP) corridor. Boasting a transportation capacity over 5 Mtpa, the pipeline stands as a testament to skilled engineering. The installation of an interconnecting pipeline between the two gas plants began with Handley Surveys providing lead survey works on this project.

The Challenge

Facing a demanding environment characterised by nearly 200 survey requests, each encompassing up to 10 jobs, it was critical to employ a data and time management system equipped to grapple with such a robust workload. With only a finite team and resources at our disposal, the potential oversight of crucial data—essentially ‘dropping the ball’—was a continuous concern that necessitated an effective solution.

Rising above this challenge, our Lead Surveyor demonstrated great ingenuity by developing a decisive data management & reporting system. This accomplishment didn’t merely contribute to the project—it was the linchpin in its success. This system managed the job complexity while mitigating risk, further solidifying our reputation as a dependable industry partner and authority.

Our Solution

In the throes of busy projects, where a singular on-site surveyor contends with a multitude of urgent tasks, a centralised, transparent management system is imperative. Such an organised framework drives the workflow, making a tangible difference in the face of inevitable time management challenges. To preempt possible conflicts, our team devised a tactical approach—the daily shared Survey Schedule.

Each afternoon, this clear roadmap for upcoming surveys is shared with clients and Woodside, fostering transparency and reinforcing accountability through visibility. Our surveyors are at the heart of this process, ensuring every work request is skillfully scheduled and executed.

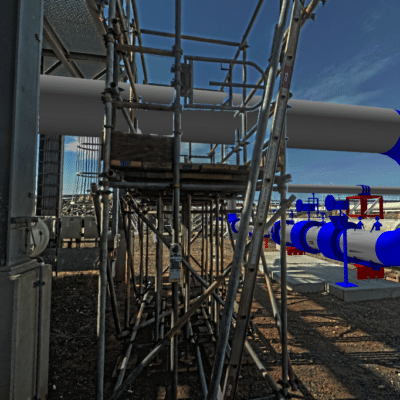

Very pleased with the standard of service received from Handley’s with regards to site survey requirements and in particular the NEO construction activities. The standard received has enabled the civils and SMP to work together in a seamless manner with a pleasing result that enabled both bridge structures and all trestles to be erected with no onsite modifications. Reporting has been completed in a timely manner and a number of discrepancies raised to allow engineering “adjustments” to be made in a timely manner.

The Results

Leveraging our robust systems empowered us to glean crucial insights, exposing design errors that had gone unnoticed by the client. This vigilant review shielded Woodside from incurring significant rework expenses. We accorded this by conducting meticulous comparisons between the Issued For Construction (IFC) drawings and the supplied model, allowing for adjustments ahead of schedule.